Laurelville, OH Wastewater Treatment Plant

CLIENT:

City of Laurelville

LOCATION:

Laurelville, OH

APPLICATION TYPE:

Municipal

TECHNOLOGY USED:

LemTec™ Biological Treatment Process

BACKGROUND:

Nestled in the hills of Hocking County, Ohio, lies the quaint village of Laurelville. Founded in 1871, Laurelville boasts a population of around 500 residents. The village takes its name from the laurel trees that once graced the area. Today, Laurelville offers a peaceful atmosphere, perfect for those seeking a small-town escape. Visitors can explore the nearby Hocking State Forest, or enjoy the shops and restaurants that dot the village streets.

CUSTOMER PROBLEM:

Laurelville’s wastewater treatment plant, which is owned and operated by the village, discharges treated wastewater into the nearby Brimstone Creek. Recently, their wastewater treatment plant upgrade became a top city priority due to non-compliance with EPA regulations. The 50-year-old facility had been unable to meet winter ammonia limits in the effluent and was still unable to achieve satisfactory results after several modifications including the addition of enhanced aeration and a biofilter. Additionally, the synthetic liners in the lagoons had deteriorated due to age. Another challenge the city faced was the plant was originally supposed to begin a major upgrade in late 2020 however, the pandemic delayed the process and increased costs. The city reached out to Lemna to provide a cost-effective solution for enhancing their existing facility, to accommodate projected flows as well as meet BOD, TSS and ammonia limits.

OUR RECOMMENDATION:

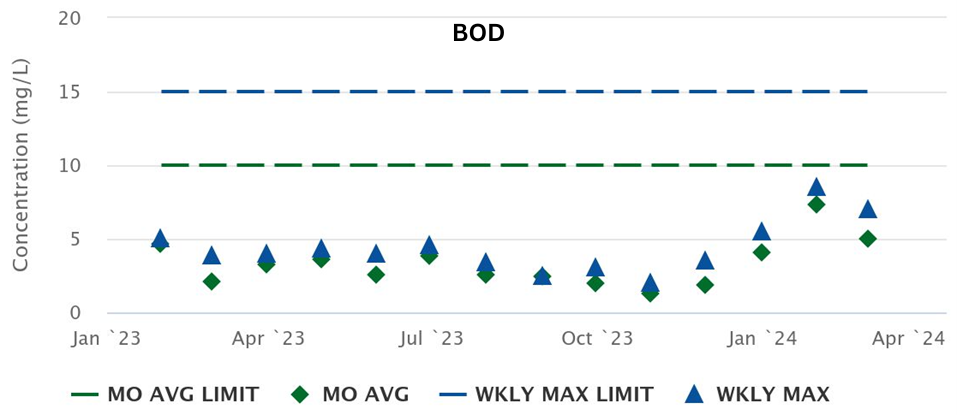

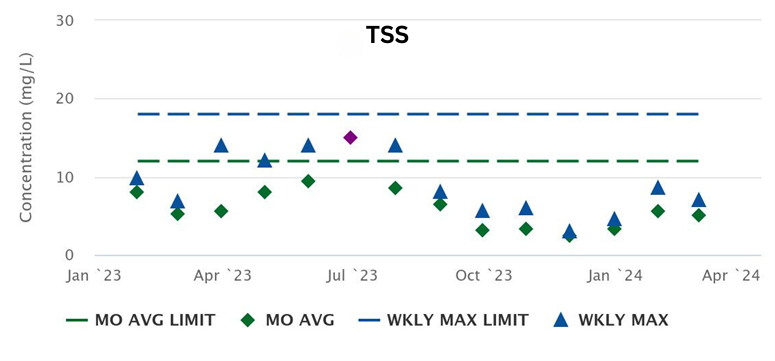

Lemna proposed and designed a new system that utilized their two existing lagoons running in series to handle a total design flow of 0.200 MGD, with each lagoon being 12 feet deep. In the first lagoon cell, a custom designed LemTec™ Reverse Miter Hydraulic Baffle was installed to minimize short-circuiting. The first complete mix cell in the LBTP process was aerated and aggressively mixed, promoting rapid BOD5 removal by bacteria. Ammonia was also removed by heterotrophic bacteria present in the complete mix cell. Water then flowed into a partial mix cell before entering the second lagoon, divided into a partial mix cell and a settling cell. Both lagoons were covered with Lemna’s LemTec™ Modular Insulated Cover, enhancing treatment efficiency by stabilizing temperatures, filtering sunlight, and preventing surface disturbances. The LemTec™ Polishing Reactor further treated BOD and ammonia, using submerged media modules to encourage bacterial growth. This reactor produced effluent levels below 10 mg/l for BOD and TSS, and as low as 1 mg/l for NH3-N that would allow the plant to safely discharge to Brimstone Creek. The oxygen requirements for the system were met by two 50 HP blowers, one of which was continuously operated.

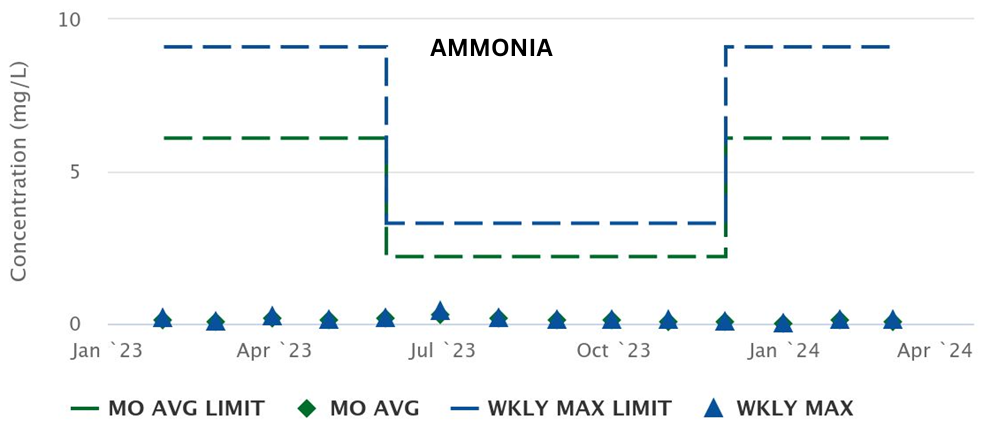

RESULTS:

Laurelville city personnel have discovered the Lemna solution to be highly dependable and economically advantageous in addressing their wastewater challenge. Over time, the system has consistently surpassed acceptable thresholds for BOD, TSS, and Ammonia levels, guaranteeing adherence to regulations and instilling confidence in the community’s discharge system. The implementation of the biological treatment lagoon system not only safeguarded local resources but also paved the way for future population expansion. Addressing immediate concerns highlighted the municipality’s dedication to environmental stewardship and the community’s well-being.

EFFLUENT GRAPHS:

LITERATURE:

Let’s Get Started

We are happy to help and look forward to hearing from you. Please contact us with any questions or inquiries.