Total Nitrogen Removal

Integrating Lagoon Technologies to Solve Every Treatment Challenge from Influent to Effluent

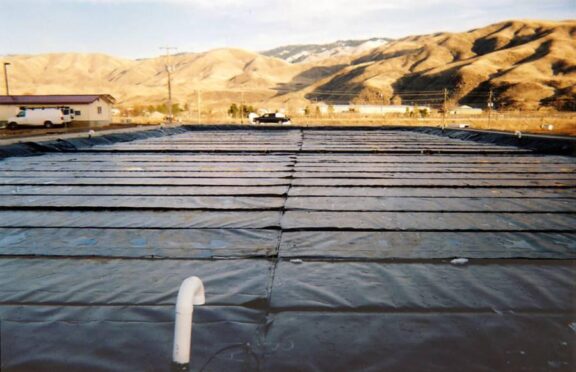

Following the LPR, denitrification is accomplished via carbon addition and filtration. The LemTec up-flow sand filter consists of in‐ground up‐flow biologically active filters and modular components that can be sized to meet the project’s requirements. Carbon enhancement is accomplished by introducing a soluble carbon source into the wastewater ahead of the filter. Bacteria metabolize the carbonaceous material in the wastewater as their food source, and consume the oxygen in the nitrate, releasing nitrogen gas into the air.

Expertise as a leader in this industry for 40+ years, an arsenal of cutting-edge technologies and a groundbreaking approach set LET apart by delivering optimized solutions for wastewater applications including Denitrification to meet clients’ objectives efficiently and cost-effectively.

We maximize LET’s innovative technologies as stand-alone solutions or use the Advanced Integrated Lagoon Technologies (AILT) approach to design and create the best process with technologies integrated as components that successfully meet every challenge from influent to effluent.

Learn more about Sierra Nevada Brewing Company – Ashville, North Carolina

Learn more about Sierra Nevada Brewing Company – Ashville, North Carolina